The Fujian Xiapu Nuclear Power Plant, located in Xiapu County, Fujian Province, is a major nuclear project in China. It uses the AP1000 technology, which is one of China’s self-developed third-generation nuclear technologies. The project began investment in 2008 and completed construction in 2018. With an installed capacity of 130,000 kW, the power plant plays a crucial role in solving the energy supply problem in the coastal area of Fujian Province.

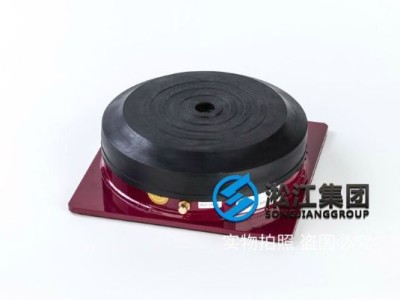

During the construction of the project, Songjiang Group provided high-performance rubber joint solutions to meet the specific needs of the power plant’s pipeline systems. These rubber joints play a key role in reducing vibration and noise in weak acid and alkali pipelines, ensuring the safe and efficient operation of the nuclear power plant.

Project Requirements and Solution:

Project Requirements and Solution:

Nuclear power plant pipelines face extreme temperature, pressure, and corrosive media conditions. Therefore, components used for pipe connections must meet high standards of reliability and durability. Songjiang Group provided custom rubber joints designed specifically for the plant’s pipeline systems. These joints are highly resistant to corrosion, high temperatures, and pressure, while also effectively reducing vibrations and noise.

Our custom-designed rubber joints were made from high-quality materials and underwent strict quality control to meet the safety standards required in the nuclear industry. By absorbing vibrations and minimizing noise, these joints ensured the stable and safe operation of the plant’s pipeline systems.

Product Features:

-

Excellent Corrosion Resistance: The rubber joints used in the nuclear power plant pipelines are made from high-quality materials that withstand corrosion from weak acids and alkalis.

-

Vibration and Noise Reduction: The rubber joints are designed to reduce vibration and noise caused by the operation of nuclear plant equipment, improving the working environment.

-

High-Pressure Resistance: The rubber joints can withstand high-pressure conditions up to several tens of megapascals, ensuring the safety and reliability of the plant’s pipeline system.

-

Customized Design: We provided tailored solutions for the Xiapu Nuclear Power Plant, ensuring that our rubber joints met specific requirements in terms of size, materials, and performance.

Project Results and Value:

The successful installation of Songjiang Group’s rubber joints significantly enhanced the stability and performance of the Fujian Xiapu Nuclear Power Plant’s pipeline system. The product’s high performance and reliability helped reduce maintenance costs and improve operational efficiency.

This project further solidified Songjiang Group’s reputation in the nuclear power sector, demonstrating our capability to meet the demanding requirements of critical infrastructure projects. Our rubber joints have since gained recognition and are poised for use in future nuclear projects.

II. [Fujian Xiapu Nuclear Power Plant Project] Rubber Expansion Joint Contract Scanned Copy:

Our company’s new website is now live, featuring the latest product introductions. For more details, please visit

Our company’s new website is now live, featuring the latest product introductions. For more details, please visit ![[FKM] DN100 Fluorine Single Sphere Rubber Joint “Fully Automatic Production Plant”](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/FKM-DN100-Fluorine-Single-Sphere-Rubber-Joint-Fully-Automatic-Production-Plant.jpg&h=300&w=400&zc=1)

![[PTFE Lined] Single Sphere Rubber Joint “SUS304+EPDM+PTFE”](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/PTFE-Lined-Single-Sphere-Rubber-Joint-SUS304EPDMPTFE-1-1.jpg&h=300&w=400&zc=1)

![[New product] Ductile flange twin sphere rubber joint “not easy to rust”](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/New-product-Ductile-flange-twin-sphere-rubber-joint-not-easy-to-rust-1.jpg&h=300&w=400&zc=1)

![[ANSI] Single Sphere Rubber Joint DN80 “American Standard”](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/ANSI-Flange-Single-Sphere-Rubber-Joint.jpg&h=300&w=400&zc=1)

![[New Product] Ductile Flange DN100*80 Concentric Reducer Rubber joint](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/New-Product-Ductile-Flange-DN10080-Concentric-Reducer-Rubber-joint-1.jpg&h=300&w=400&zc=1)

![[CNPC Chuanqing Drilling Company Mud Pipeline] Single Sphere Rubber Expansion Joint Contract](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/picture-of-CNPC-Chuanqing-Drilling-projects.jpg&h=300&w=400&zc=1)