In the dynamic landscape of automotive manufacturing, Suzhou Bosch Automotive Components stands out as a pinnacle of innovation and reliability. Specializing in various automotive components, Suzhou Bosch has consistently delivered top-notch solutions tailored to meet the ever-evolving demands of the industry. In this case study, we delve into the integration of Songjiang Metal Bellows manufactured by Shanghai songjiang group which specializes in producing single rubber expansion joints and metal bellows, exemplifying its multifaceted applications and the resultant benefits.

The Role of Metal Bellows in Automotive Manufacturing:

Metal Bellows, renowned for their robustness and adaptability, play a pivotal role in enhancing automotive performance. Acting as compensators, these bellows effectively mitigate the impact of temperature and pressure fluctuations within vehicle systems, ensuring stability and longevity. Moreover, Metal Bellows absorb vibrations and shocks, thereby minimizing wear and tear on critical components and enhancing overall durability. Their ability to reduce noise and vibration transmission enhances passenger comfort and mitigates driver fatigue. Additionally, Metal Bellows facilitate axial and radial displacement compensation, safeguarding against structural damage and excessive stress. Furthermore, their utility extends to fluid and gas sealing and transmission, ensuring seamless flow between automotive systems while preventing leaks and damage.

Case Study: Integration of Metal Bellows in Suzhou Bosch Automotive Components:

Suzhou Bosch Automotive Components has embraced Metal Bellows as a cornerstone component in its manufacturing process. By incorporating Metal Bellows into various automotive systems, Suzhou Bosch has achieved remarkable enhancements in performance, reliability, and user experience.

In the chassis control system, Metal Bellows effectively compensate for temperature-induced expansions and contractions, maintaining precise alignment and optimizing handling dynamics. Furthermore, in the exhaust system, Metal Bellows absorb vibrations and reduce noise transmission, resulting in a quieter and smoother driving experience for passengers.

In the powertrain system, Metal Bellows facilitate seamless torque transmission while compensating for axial and radial displacements, ensuring optimal power delivery and minimizing drivetrain wear. Moreover, in fluid transmission systems, Metal Bellows serve as reliable seals, preventing leakage and ensuring efficient fluid transfer between components.

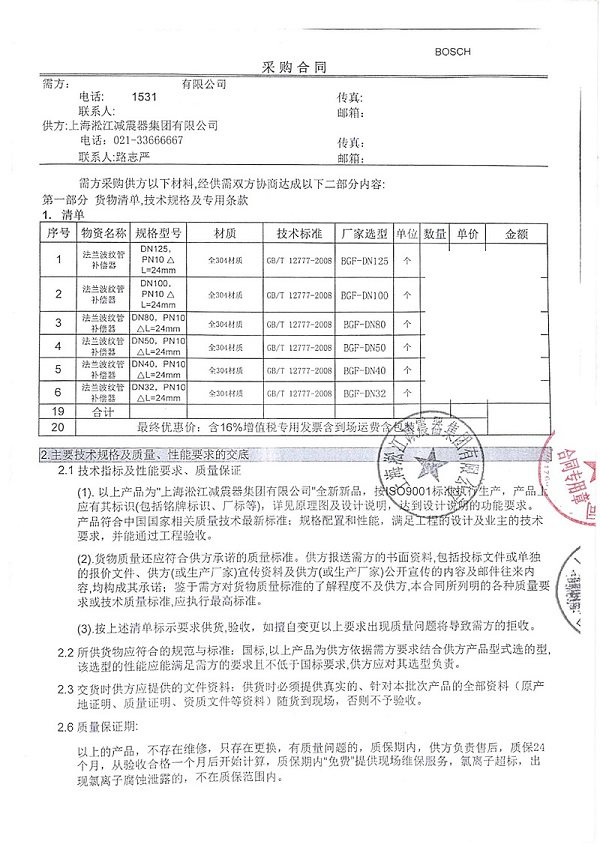

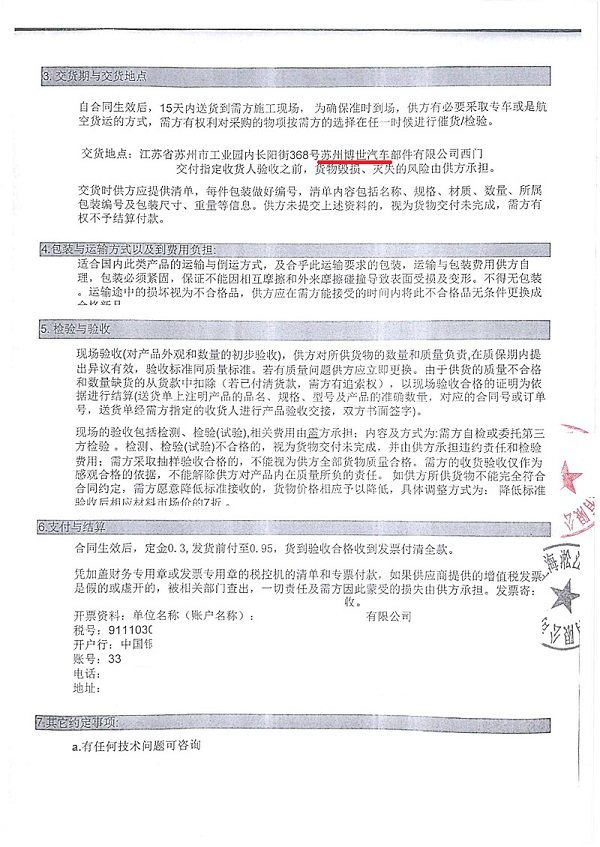

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In conclusion,the successful integration of Metal Bellows into Suzhou Bosch Automotive Components exemplifies the synergy between innovative technology and automotive engineering excellence. By harnessing the diverse capabilities of Metal Bellows, Suzhou Bosch has achieved superior performance, reliability, and comfort in its automotive systems, setting a benchmark for the industry. As automotive manufacturing continues to evolve, Metal Bellows remain indispensable components, driving advancements in vehicle performance and user satisfaction.

Related links:Metal Expansion Joint

![[PTFE Lined] Single Sphere Rubber Joint “SUS304+EPDM+PTFE”](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/PTFE-Lined-Single-Sphere-Rubber-Joint-SUS304EPDMPTFE-1-1.jpg&h=300&w=400&zc=1)

![[JIS] Japanese Standard single sphere rubber joint](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/JIS-Japanese-Standard-single-sphere-rubber-joint-1.jpg&h=300&w=400&zc=1)

![[FKM] DN100 Fluorine Single Sphere Rubber Joint “Fully Automatic Production Plant”](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/FKM-DN100-Fluorine-Single-Sphere-Rubber-Joint-Fully-Automatic-Production-Plant.jpg&h=300&w=400&zc=1)

![[Nanchang Qingshan Lake Sewage Treatment Plant] DN2000 Single Sphere Rubber Expansion Joint Contract](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/【Nanchang-Qingshan-Lake-Sewage-Treatment-Plant】DN2000-Single-Sphere-Rubber-Expansion-Joint-Contract.jpg&h=300&w=400&zc=1)

![[CNPC Chuanqing Drilling Company Mud Pipeline] Single Sphere Rubber Expansion Joint Contract](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/picture-of-CNPC-Chuanqing-Drilling-projects.jpg&h=300&w=400&zc=1)