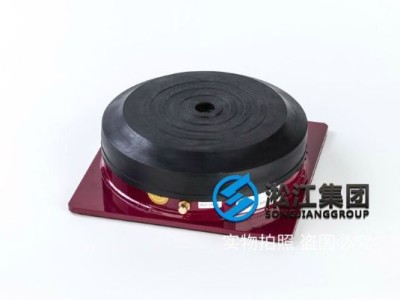

Single Rubber expansion joints play a crucial role in optimizing operations within automotive factories, offering versatile solutions to various challenges encountered in production processes. Let’s delve into a specific case where the implementation of Songjiang single rubber expansion joints has significantly enhanced efficiency and functionality at Ansen Automotive Manufacturing Plant.

Located in the heart of automotive manufacturing, Ansen Automotive Plant is renowned for its commitment to quality and innovation. Facing the dynamic demands of modern production, Ansen sought solutions to streamline its operations and enhance productivity. One area of focus was the optimization of its pipeline systems, crucial for maintaining the seamless flow of materials and fluids throughout the facility.

Ansen’s collaboration with a leading provider of vibration control solutions led to the implementation of Songjiang single rubber expansion joints in several key areas within the factory:

Spray Pipeline Systems: Ansen utilized rubber expansion joints to connect various components within its spray pipeline systems, including paint sprayers and paint booths. These joints effectively managed the expansion of pipelines, adapting to temperature fluctuations and pipeline vibrations while minimizing the risk of paint leaks and ensuring a smooth painting process.

Exhaust Systems: The factory’s exhaust systems, essential for maintaining air quality and removing pollutants, were optimized with rubber expansion joints. These joints facilitated the connection of exhaust treatment equipment and pipeline networks, effectively managing the expansion and vibrations of the system while minimizing the risk of gas leaks and sewage spills.

Hydraulic Systems: Hydraulic systems play a vital role in controlling the movement of machinery within the factory. Ansen integrated rubber expansion joints into its hydraulic pipelines, ensuring the seal and stability of the pipes during system operation. These joints effectively managed expansion and vibrations, contributing to the smooth functioning of hydraulic equipment.

Water Supply Systems: Ansen’s water supply systems, crucial for equipment operation and employee welfare, were enhanced with rubber expansion joints. These joints facilitated the connection of pipeline networks, managing the expansion of water flow and pipeline vibrations while minimizing the risk of water leaks and pipe damage.

In conclusion, the implementation of Songjiang single rubber expansion joints at Ansen Automotive Manufacturing Plant has significantly improved operational efficiency and functionality. By effectively managing expansion, vibrations, and fluid flow within critical systems, these joints have played a pivotal role in ensuring the smooth operation of the factory. As automotive manufacturing continues to evolve, Ansen remains committed to leveraging innovative solutions to drive efficiency and excellence in its production processes.

Related links:[EPDM] Ductile Flange Single Sphere Rubber Joint

![[PTFE Lined] Single Sphere Rubber Joint “SUS304+EPDM+PTFE”](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/PTFE-Lined-Single-Sphere-Rubber-Joint-SUS304EPDMPTFE-1-1.jpg&h=300&w=400&zc=1)

![[PVC Flange] Twin Sphere Rubber Joint DN100](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/PVC-Flange-Twin-Sphere-Rubber-Joint-1.jpg&h=300&w=400&zc=1)

![[Central Asia Natural Gas Pipeline Uzbekistan Section] Single Sphere Rubber Expansion Joint Contract](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/Central-Asia-Natural-Gas-Pipeline-Uzbekistan-Section-Single-Sphere-Rubber-Expansion-Joint-Contract-1.jpg&h=300&w=400&zc=1)