The CNBM International ABMC 10,000 Tons Per Day Cement Production Line Project equipped with songjiang single rubber expansion joints stands as a hallmark of international engineering collaboration and technological advancement . Developed by the ARKAN Building Materials Group in Abu Dhabi and executed by CNBM International Overseas Business Development Company, this EPC turnkey project underscores the importance of high-quality infrastructure components in ensuring project success.Signed on March 19, 2006, with a contract amount of $276,313,000, the project commenced construction on September 16, 2007. Equipment installation was completed by September 2009, followed by single equipment commissioning using diesel generators provided by the owner in October 2009. By April 2011, the material crushing and pre-homogenization sub-item feeding commissioning began. The plant was successfully ignited on November 7, 2012, and clinker production started on November 12. Currently, the project is advancing towards material feeding commissioning, performance testing, and comprehensive handover.Integral to this project’s infrastructure are the DN250 single rubber expansion joints supplied by Shanghai Songjiang Vibration Isolator Group Co., Ltd. These high-performance components played a crucial role in ensuring the durability and efficiency of the cement production line.

Technical Specifications and Benefits

The DN250 single rubber expansion joints, also known as flexible rubber joints, rubber soft connections, and vibration isolators, are designed to accommodate various industrial needs. Key specifications include:

Product Specifications: DN250mm

Pressure Capacity: 0.6-2.5MPa

Vibration Reduction Grade: Grade A, offering superior vibration reduction performance

Certification: ISO9001-2008

These joints are made from environmentally friendly, high-quality natural synthetic rubber, ensuring they are free from toxic substances like lead. They are designed to operate within a temperature range of -40°C to 80°C, with options available for high-temperature conditions.

Advantages

Vibration and Noise Reduction: These joints significantly reduce vibration and noise, contributing to a quieter and more stable operation.

Flexibility and Convenience: Their small size, lightweight nature, and excellent elasticity make them easy to install and maintain.

Accommodating Displacement: They can handle lateral, axial, and angular displacement, making them ideal for pipelines with misalignment or non-parallel flanges.

Enhanced Performance: By reducing structural noise transmission and offering strong vibration absorption, these joints ensure optimal performance.

Wide Application: Their excellent performance makes them suitable for various industries, including chemical, construction, water supply, drainage, petroleum, light and heavy industries, refrigeration, sanitation, plumbing, fire protection, and power.

Impact on the Project

The incorporation of Shanghai Songjiang’s DN250 single rubber expansion joints was pivotal in addressing the challenges posed by significant vibration and frequent thermal changes in the cement production line. Their robust construction and superior performance helped maintain the integrity of the pipeline systems, thereby enhancing the overall efficiency and reliability of the cement production process.

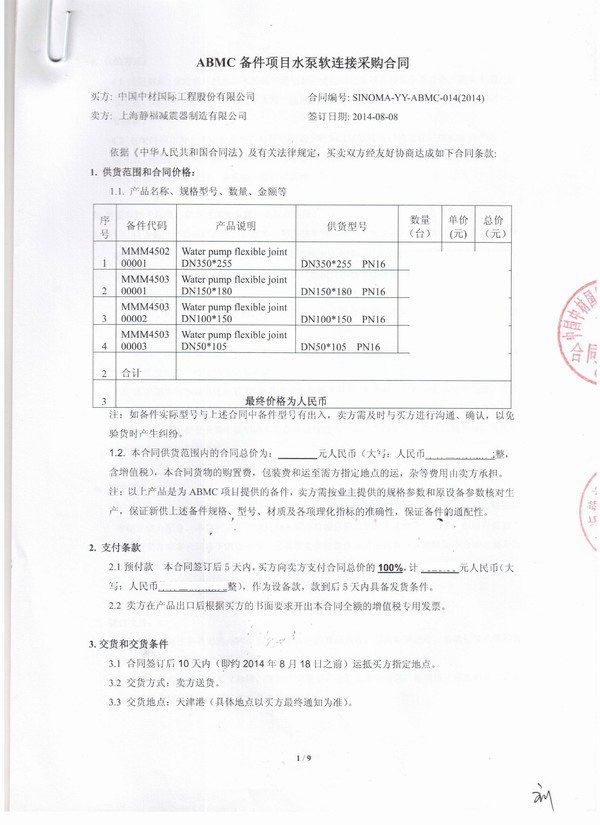

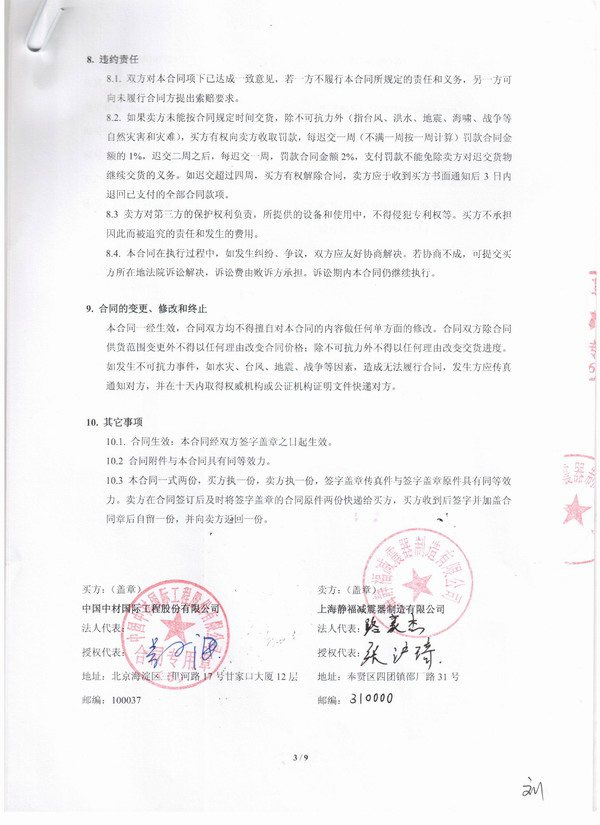

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In conclusion,the CNBM International ABMC 10,000 Tons Per Day Cement Production Line Project exemplifies the successful integration of advanced engineering solutions in large-scale industrial projects. Shanghai Songjiang’s single rubber expansion joints not only met but exceeded the project’s stringent requirements, showcasing their indispensable role in modern industrial infrastructure. This case study highlights the importance of selecting high-quality components to achieve long-term operational success and stability.

Related links:[EPDM] Ductile Flange Single Sphere Rubber Joint

![[EPDM] Ductile Flange Single Sphere Rubber Joint](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/EPDM-Single-Sphere-Rubber-Joint-Product-Photo-1.jpg&h=300&w=400&zc=1)

![[ANSI] Single Sphere Rubber Joint DN80 “American Standard”](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/ANSI-Flange-Single-Sphere-Rubber-Joint.jpg&h=300&w=400&zc=1)

![[Stainless Steel Flange] Twin Sphere Rubber Joint DN150](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/stainless-steel-flanged-twin-sphere-rubber-joint-1.jpg&h=300&w=400&zc=1)

![[Caofeidian Port Seawater Desalination Project] Single Sphere Rubber Expansion Joint Contract](https://single-rubber-expansion-joint.com/wp-content/themes/xsding.2021.8.2/timthumb.php?src=http://single-rubber-expansion-joint.com/wp-content/uploads/2022/04/Caofeidian-Port-Seawater-Desalination-Project-Single-Sphere-Rubber-Expansion-Joint-Contract-1.jpg&h=300&w=400&zc=1)